The Ultimate Guide to PU Injection Waterproofing

In the world of construction and home maintenance, ensuring the integrity and longevity of structures against water damage is paramount. One innovative solution that has gained significant traction for its effectiveness in combating leaks and dampness is PU (Polyurethane) injection waterproofing. This detailed guide dives into the essence of PU injection waterproofing, its numerous benefits, essential tips for selecting a contractor, and an overview of the materials used in the process.

What is PU Injection Waterproofing?

PU injection waterproofing is a specialized method utilized to seal and repair cracks, joints, and voids in concrete structures, preventing water ingress. The process involves injecting a polyurethane resin into the affected area under high pressure. This resin reacts with water to expand and form a tight, impermeable seal, effectively stopping leaks and providing a durable waterproof barrier.

This technique stands out for its versatility and efficacy, making it an ideal choice for a wide range of applications, including basements, tunnels, water tanks, and roofs. Its targeted approach allows for addressing specific problem areas without the need for extensive surface preparation or disruption to the surrounding structure.

Benefits of PU Injection Waterproofing

Efficient Leak Repair

PU injection waterproofing offers a quick and effective solution to water leak problems. The injected resin rapidly expands to fill cracks and voids, ensuring that even the smallest leaks are sealed.

Durability

The polyurethane resin used in this method creates a strong, durable bond with concrete, resisting wear and tear over time. This long-lasting seal protects structures against future water damage.

Minimal Disruption

Unlike other waterproofing methods that require extensive surface preparation or complete access to one side of the structure, PU injection can be performed with minimal disruption to the building’s occupants or operations.

Cost-Effectiveness

By directly addressing the source of leaks, PU injection waterproofing can save property owners considerable expenses in potential repair costs and property damage due to water infiltration.

Environmentally Friendly

Many polyurethane resins used in PU injection are environmentally friendly, containing no volatile organic compounds (VOCs), making this a safe choice for waterproofing projects.

Choosing the Right Contractor for PU Injection Waterproofing Works

Experience and Expertise

Look for a contractor with a proven track record in PU injection waterproofing. Experienced professionals will be able to accurately diagnose the source of water ingress and recommend the most effective treatment.

Licensing and Certification

Ensure the contractor is licensed and certified to perform waterproofing works. Certifications from reputable organizations can indicate a higher level of professionalism and knowledge.

Quality of Materials

Inquire about the types of polyurethane resins and injection equipment the contractor uses. High-quality materials and modern, well-maintained equipment contribute to a more effective and durable waterproofing job.

Warranty and After-Service Support

A reliable contractor should offer a warranty for their work, providing peace of mind that any future issues will be addressed. Additionally, prompt after-service support in case of any problems is a sign of a reputable provider.

Customer Reviews and References

Check online reviews and ask for references from past projects similar to yours. Feedback from previous clients can offer valuable insights into the contractor’s reliability, quality of work, and customer service.

Materials Used in PU Injection Waterproofing

Polyurethane Resin

The core material in PU injection waterproofing is the polyurethane resin. These resins come in various formulations, with some designed to react quickly with water for rapid expansion and sealing, while others may be formulated for slower expansion, allowing deeper penetration into wider cracks.

Injection Ports and Packers

To inject the resin into the concrete, technicians install small injection ports or packers at strategic locations along the crack. These allow for precise control of the resin injection, ensuring that the entire crack is filled.

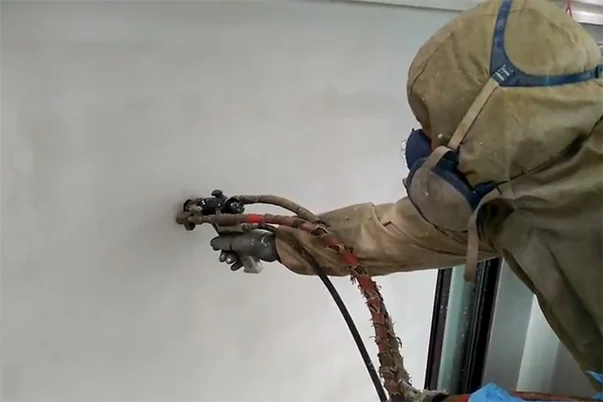

Injection Equipment

The injection process requires specialized equipment, including high-pressure pumps and hoses, to deliver the polyurethane resin into the cracks at the correct pressure and volume. Professional contractors will have access to the latest technology in injection equipment, facilitating a more efficient and effective waterproofing process.

Conclusion

PU injection waterproofing represents a sophisticated solution to the age-old problem of water infiltration in structures. Its ability to quickly and effectively seal cracks and voids, combined with the durability and cost-effectiveness of the treatment, makes it a preferred choice for many property owners and managers. When considering PU injection waterproofing, selecting the right contractor is crucial. By focusing on experience, material quality, and customer service, property owners can ensure that their waterproofing project is handled professionally and successfully. With the right approach, PU injection waterproofing can protect your structure from water damage, preserving its integrity and value for years to come.